Welcome to this engineering-focused article about Automatic Test Equipment (ATE).

ATE is a type of testing system used to automatically test electronic components and systems.

Additionally, I'll address how ATE contributes to product quality and reliability, as well as its ability to be customized and integrated with other testing systems.

If you're interested in learning more about Automatic Test Equipment and its applications in various industries, keep reading!

Introduction to Automatic Test Equipment (ATE)

Formal definition:

Test equipment that makes two or more tests in sequence without manual intervention; it usually stops when the first out-of-tolerance value is detected.

So, who needs accurate and reliable test results? Everyone!

Automatic Test Equipment (ATE) is an essential component of electronic testing, used to evaluate the functionality, performance, quality, and stress of electronic devices and systems across multiple industries.

Components of ATE

ATE comprises stimulus, measurement, and switching components that are computer-controlled and process software routines specifically designed to test a particular electronic device or system.

The components are integrated into a single assembly, and the equipment can be configured to test a range of devices, including LRUs, WRAs, circuit cards, and All-Up-Rounds.

ATE also includes Automatic Test Pattern Generation (ATPG), which sends test patterns to the device under test (DUT).

ATE and Test Program Sets (TPS)

ATE also includes Test Program Sets (TPS), which are interface hardware and ancillary equipment that connect the Unit Under Test (UUT) to the ATE, along with test program software specific to the UUT and the required documentation.

These elements combine to create a cohesive system that can rapidly and accurately evaluate electronic devices.

The uses and applications of ATE

ATE has widespread applications in various industries, including defense and aerospace, automotive, and industrial automation.

ATE is a useful tool for data acquisition and diagnostics, which enables quick and accurate testing of electronic devices.

It also plays a critical role in printed circuit board tests and equipment tests, allowing for rapid and efficient testing of components, far faster than if it were done manually.

ATE is a vital tool in the electronics test scene today. More of this in the end of this article.

Benefits of Using ATE

Automated test equipment (ATE) has revolutionized the testing industry, providing businesses with many benefits that were once not possible.

Let's explore the advantages of automated testing, including its ability to save time and money while improving product accuracy and reliability.

Reduced Test and Cycle Times

Automated testing allows for reduced test and cycle times, which leads to quicker turnaround times and faster product delivery.

This is particularly beneficial for businesses operating in time-sensitive industries where quick testing is essential.

Improved Accuracy and Reliability

ATE is more accurate and reliable than manual testing, as it eliminates human error and ensures consistent and repeatable results.

This, in turn, can lead to improved product quality and customer satisfaction.

Increased Test Coverage and Depth

Automated testing can test a more extensive range of scenarios and test cases than manual testing, which helps increase test coverage and depth.

This ensures that the product is thoroughly tested, minimizing the possibility of errors and faults.

Reusability of Test Suite

Automated tests can be reused on multiple products, which saves time and resources in the long run.

This is particularly beneficial for businesses that produce similar products or products with similar features.

Faster Feedback Cycles

Automated testing provides faster feedback cycles, allowing developers to detect issues earlier in the development cycle.

This reduces the time and cost associated with fixing issues later in the development process.

More Time for Developers and Testers

Automated testing frees up developers and testers to work on more challenging projects that require human expertise.

This improves the overall quality of the product and enables businesses to focus on more innovative projects.

Cost Savings

Automated testing can help businesses reduce testing costs by using fewer resources and reducing the time required for testing.

This can result in significant cost savings for businesses of all sizes.

Automatic Test Equipment vs Manual Test Equipment

Software testing is an essential aspect of software development that helps ensure the quality and accuracy of the final product.

By selecting the right approach for each project's needs, businesses can ensure that their products are thoroughly tested and meet the desired quality and accuracy standards.

Manual Testing vs. Automation Testing

Manual testing and automation testing are two different approaches to software testing.

Manual testing involves a human tester manually executing test cases without the use of scripts or tools.

This approach is more time-consuming and can be prone to human errors, but it is better suited for complex scenarios that require human expertise.

Automation testing, on the other hand, uses tools and scripts to execute tests.

This approach is more efficient and can cover a larger number of device and OS permutations, but it requires coding and test maintenance.

Automation testing is well-suited for tests that can be easily scripted and do not require human expertise.

Best Suited Testing Scenarios

Different types of testing scenarios require different testing approaches, and it is essential to choose the right approach for each project's needs.

Here are some testing scenarios and which approach is best suited for each one:

Exploratory Testing, Usability Testing, and Ad-hoc Testing are best suited for manual testing due to its flexibility in quickly seeing results and the need for human expertise.

Regression Testing, Load Testing, Performance Testing, and Repeated Execution are better suited for automation testing due to its efficiency in running multiple tests with no significant hassles each time.

Hardware and Software Testing with ATE

Components of ATE Systems

ATE systems typically consist of five main components: hardware, software, test instruments, signal sources, and test probes or handlers.

These components work together to automate the testing process, reducing the time and cost associated with manual testing. Just to name a few:

Workstations, digital storage oscilloscope (DSO), digital multimeter, or inductance, capacitance, and resistance (LCR) meter, arbitrary waveform generator (AWG), function generator, pulse generator, or radio frequency (RF) generator and others.The wikipedia has a list of physical components and platforms:

https://en.wikipedia.org/wiki/Automatic_test_equipment

Types of Testing with ATE

ATE can be used to perform a variety of tests on hardware and software products.

Here are some of the most common types of testing that can be performed using ATE:

| Used in: | Description: |

|---|---|

| Functionality Testing | This type of testing is used to verify that a product functions as designed. ATE can be used to automate the process of running test cases to ensure the product meets the desired specifications. |

| Compatibility Testing | Compatibility testing is used to make sure a product functions in its targeted use environment. ATE can be used to simulate a variety of different environments to ensure the product functions as expected in each one. |

| Usability Testing | Usability testing is performed to provide an independent analysis of a product in terms of how easy or difficult it is to use. ATE can be used to simulate different scenarios and user interactions to ensure the product is intuitive and easy to use. |

| Regression Testing | Regression testing allows for repetitive tests to be performed quickly and easily by scripting the product with one of many different languages. ATE can be used to automate regression testing, ensuring that the product functions as expected after each change or update. |

ATE Customization

Automatic test equipment can be customized to suit specific testing requirements and is a valuable tool for testing complex products and systems.

Custom automated test equipment design requirements should prioritize immediate needs as well as potential future requirements to ensure a flexible and effective test system.

Customizing Automated Test Equipment

ATE systems are designed to be flexible and can be configured to perform a wide range of tests depending on the product being tested and the specific requirements of the test.

Customization of ATE systems may involve modifying existing test equipment or developing new hardware or software to meet the specific testing needs.

The ability to customize ATE systems makes them a valuable tool for testing complex products and systems.

Automated Testing vs. Manual Testing

The decision to use automated or manual testing depends on factors such as the complexity of the product being tested and the cost of manufacturing and testing it.

Automated testing is now widely used for testing electronic products due to the cost of test equipment and software tools reducing in line with Moore's Law.

However, there may be opposition to introducing automated test depending on the application.

Custom Automated Test Equipment Design Requirements

Custom automated test equipment design requirements should prioritize what is needed immediately as well as what may be needed in the future.

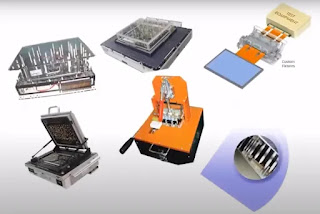

Automated test systems come in all shapes and sizes and can leverage expertise from a variety of fields such as optical, RF, mechanical, electrical, software, and more.

When designing custom automated test equipment, it is important to consider the specific testing needs of the product and ensure that the test system is flexible enough to accommodate future changes and updates.

Key Features of ATE

Factors to Consider When Purchasing Automatic Test Equipment

When purchasing automatic test equipment, it's important to consider several key features:

- Cost effectiveness

- Robustness

- Ease of use

- Durability/reliability

- Expandability

- High test accuracy

- Diagnostic and self-test capabilities

- Optimization for automation

- Meeting specific standards or requirements

- Future testing needs

- Cloud-based testing solutions

What you should keep in mind:

| Used in: | Description: |

|---|---|

| Cost-effectiveness | It's important to choose equipment that offers the best value for money, without compromising on quality or performance. |

| Robustness | ATE systems should be able to withstand the rigors of testing, which can be demanding and intense. Equipment that is robust and reliable is essential to ensure accurate and reliable results. |

| Ease of use | ATE should be easy to operate, even for non-expert users. Intuitive software, simple interfaces, and clear documentation can all help to make testing more efficient and effective. |

| Durability and reliability | Automated test equipment should be built to last, with a robust and durable design that can withstand frequent use and the wear and tear of daily operation. |

| Expandability | It is important to select equipment that can grow with your needs. ATE systems that are scalable and flexible can help to meet your changing requirements over time. |

| High test accuracy | Test accuracy is critical for ensuring reliable results. High precision and accuracy are essential for producing accurate and reliable data that can be used to improve the performance of products or systems. |

| Diagnostic and self-test capabilities | ATE should have diagnostic and self-test capabilities to ensure proper testing, to detect faults and to improve system reliability. |

| Optimization for automation | ATE should be optimized for automation to save money and time. Automated equipment should require minimal manual intervention to keep it running, ensuring maximum efficiency and productivity. |

| Future testing needs | It is important to consider future testing needs when selecting ATE. The equipment should be designed to accommodate future testing requirements, such as increased capacity, new test protocols or new product testing. |

| Compliance with standards and requirements | ATE should meet specific industry standards and requirements, including safety, performance, and environmental standards. |

| Cloud-based automated testing solutions | Cloud-based automated testing solutions offer a number of benefits such as low total cost of ownership and scalability. You can access cloud-based testing solutions from anywhere, and you don't need to worry about maintaining your own servers or infrastructure. |

Cost of ATE

The cost of automatic test equipment varies depending on the complexity and size of the system.

Low-budget and medium-scale test systems can range from a few hundred dollars to several thousand dollars, while large-scale ATE systems can cost tens of thousands of dollars or more.

Example from beeptoolkit:

When Is Investing in Automated Test Equipment Worth It?

Whether or not an investment in automated test equipment is worth it depends on the application.

If manual testing is time-consuming and costly, then investing in automated test equipment may be worth it as it can save time and money in the long run.

Additionally, advancements in semiconductor manufacturing processes have increased the need for automated test equipment, driving up demand for these systems.

On the other hand, the costs associated with automation testing equipment may restrict its growth.

Benefits and Drawbacks of Automated Test Equipment

The potential benefits of automated test equipment include increased testing speed and accuracy, reduced labor costs, improved product quality, and increased production efficiency.

However, there are also potential drawbacks, such as high initial costs, the need for skilled personnel to operate and maintain the equipment, and the potential for equipment obsolescence.

Lead Time for ATE Orders

The lead time for ordering and receiving automatic test equipment can vary widely, depending on the supplier, the type of equipment, and the location of the manufacturing plant.

Typically, it can take several weeks to several months from the time an order is placed to when the equipment arrives.

The lead time may be longer for more complex or specialized equipment.

To reduce lead times, companies can increase their order volumes, work with suppliers who offer shorter lead times, and automate the order process.

It is also important to consider other factors when selecting an automated test equipment supplier, such as the quality and reliability of the equipment, the supplier's technical expertise and support, and the supplier's ability to meet specific testing requirements.

Compact Automated Test Equipment

Compact automated test equipment (ATE) can replace multiple test racks and perform multiple tests with just a change of cables, which can help to reduce lead times and improve testing efficiency.

This type of ATE is an excellent option for companies with limited space, as it can save valuable floor space by reducing the number of test racks needed.

When deciding whether to invest in automatic test equipment, it is important to consider a range of factors such as the application, the cost of the equipment, the potential benefits of increased testing speed and accuracy, reduced labor costs, improved product quality, and increased production efficiency.

It is also important to keep in mind the potential drawbacks of high initial costs, the need for skilled personnel to operate and maintain the equipment, and the potential for equipment obsolescence.

Ultimately, the decision to invest in automated test equipment will depend on the specific needs of each company and project.

Use cases

ATE has a variety of applications across multiple industries.

| Used in: | Description: |

|---|---|

| Manufacturing Industry | ATE can be used to test electronic components and systems during the manufacturing process to ensure that they meet the necessary quality standards. ATE can quickly and accurately perform tests that would otherwise take a long time to perform manually. |

| Aerospace Industry | ATE is used to test avionics and other electronic systems on aircraft. ATE can simulate real-world conditions and can perform a variety of tests, including temperature, vibration, and altitude tests. |

| Automotive Industry | ATE is used to test electronic systems and components in vehicles, such as airbag systems, anti-lock braking systems, and engine control units. ATE can detect and diagnose faults and can quickly perform a range of tests. |

| Telecommunications Industry | ATE is used to test electronic systems and components in telecommunications equipment, such as cell phones, routers, and modems. ATE can perform a range of tests, including signal quality and signal strength tests. |

| Medical Industry | ATE is used to test medical equipment and devices, such as MRI machines and heart monitors. ATE can perform a variety of tests to ensure that the equipment is functioning properly and that it meets the necessary safety standards. |

Share on…